The idea of prefabrication is known well in the building industry. A wide variety of systems was already developed during the industrialisation era, especially in large-scale industrial plant construction. Now, also the area of building services is increasingly benefiting from this type of modularization, for example in pipeline engineering and assembly.

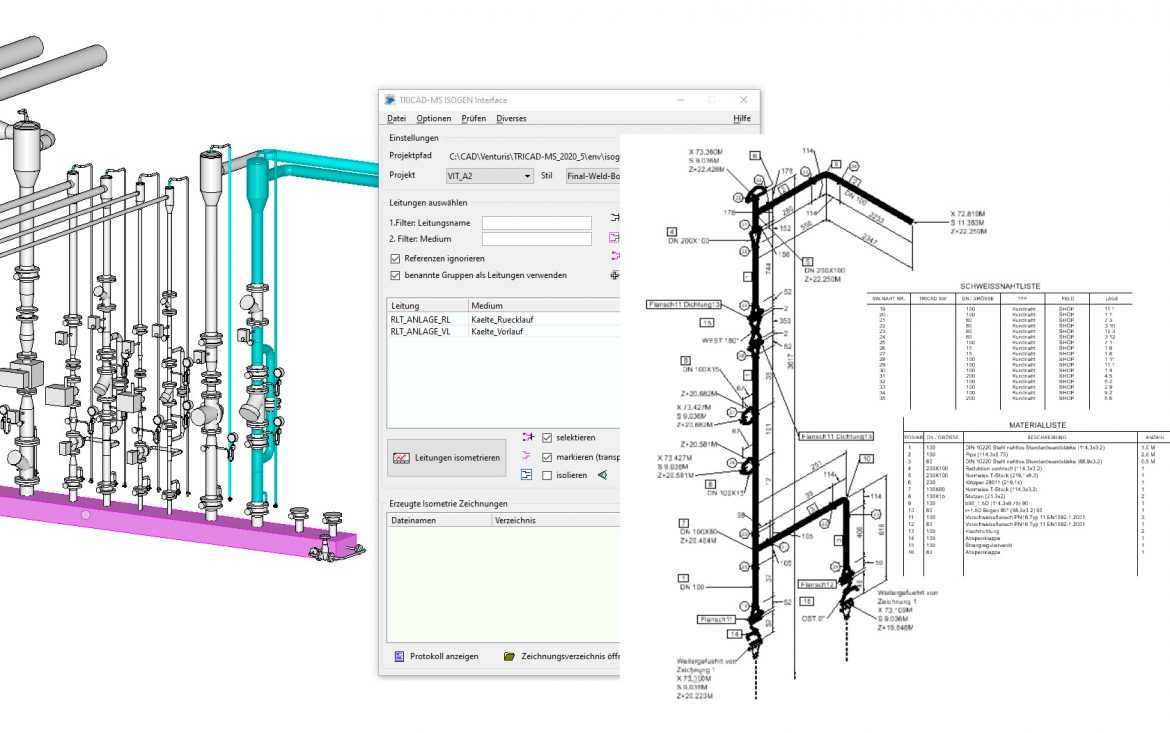

The creation of the piping isometrics directly from the 3D design is already common practice in plant design, but it is not yet commonly used in the area of building services engineering. But an increasing number of companies in this industry are recognizing the advantages. MicroStation with TRICAD MS is the standard solution for the creation of CAD plans in 3D, thus laying the foundation for isometric generation. The effort to use the data also for prefabrication is very low. Every stakeholder should benefit from this.

Isometry comes with complete information

The user can create pipe isometrics automatically from the 3D Piping module as well as sprinkler systems, sanitary and heating with the Tricad MS isometrics module. All parts and extension components can be transferred at the push of a button and exported fully automatically as fully dimensioned line isometry in all common CAD formats (e.g. DGN, DWG, PDF). All components are also exported to the drawing as a list of materials, including optional weld seam lists.

References to continuing pipelines or connections to devices are also supported as well as the use of the component names or valve designations assigned in TRICAD MS.

The visualization of welding spots, pipe bends, and valves is done according to the style specifications. Wizards to define customer and project specific evaluation rules (so-called “styles”) support the user in the development of individual representations. Sheet formats as well as plan headers and title blocks are also taken into account. Reworking efforts for the created isometrics are avoided by design.

Even complex pipe routes with gradients, surface and space jumps or across floors can be created within a few seconds. Spatial coordinates, transfer points or forged hatching are inserted fully automatically. The isometrics are then automatically or user-defined assigned to several drawings. The content and scope of the isometrics meet all requirements, even when things have to be done very quickly.

Workflow right through to pipeline prefabrication

The PCF file generated from the TRICAD MS interface can be used for prefabrication in the company’s own facilities or transferred to an external service provider/pipeline constructor. PCF files are a standard file format of common isometric or calculation programs, which is also used for stress or flow calculations. Supports that were created in TRICAD MS, including their functions such as fixed, floating or sliding bearings, can also be displayed on the isometric drawing and can therefore also be used for the stress calculation using the PCF file.

It is a simple solution with an immense added value, which is strongly recommended to companies in the building services industry. Because the cost saving potential is enormous! The advantages are obvious, no matter which medium flows through the pipes. The first companies are already benefiting from the savings and are prefabricating up to 4/5 of the pipes in their own facilities.